Furnace door of new "turtle shell" type 13T vacuum induction melting furnace

Technical field

13T vacuum induction melting furnace door belongs to the technical field of special metallurgical equipment. The above defects in the prior art:

At present, the doors of traditional induction melting furnaces adopt the structure of straight-stretched ribs. With the development of industry, the capacity requirements of vacuum furnaces are becoming higher and higher, and more and more large-tonnage vacuum furnaces. The furnace door is also getting bigger. The larger the furnace door, the stronger the atmospheric pressure, and therefore the stronger it is. Blindly thickening the thickness of the door panel and the number of ribs are not only bulky, but also difficult to meet the needs of ultra-large vacuum furnaces. The current small vacuum furnaces have a small volume, so the pressure in the vacuum state is not very large, and a flat plate is sufficient for the furnace door. However, as the furnace becomes larger, the performance of the flat plate can no longer meet the demand, and a higher strength structure is required.

13T vacuum induction melting furnace door innovation content

In order to overcome the above-mentioned shortcomings existing in the prior art, the furnace door adopting the arc-shaped "turtle shell" structure can better withstand atmospheric pressure when vacuuming, and does not need to use very thick steel plates, which can greatly reduce the weight of the equipment. It is characterized by including door frame flanges, arc inner plates, arc outer plates, stiffeners, observation windows, rings and brackets, wherein the arc inner plates and arc outer plates are welded to the door frame flanges, and the arc inner plates There is cooling water between the outer panel and the circular arc. There are several reinforcing ribs between the horizontal and vertical of the door frame flange. The observation window is set on the circular outer panel. The top of the door frame flange is provided with a ring. The side of the door frame flange is a bracket. Advantages: This structure does not need to blindly thicken the door panel and increase the number of stiffeners. It not only has a beautiful appearance, but also reduces the cost of consumption, reduces the weight of the equipment, reduces the workload, and improves the production output and efficiency.

BRIEF DESCRIPTION OF THE DRAWINGS

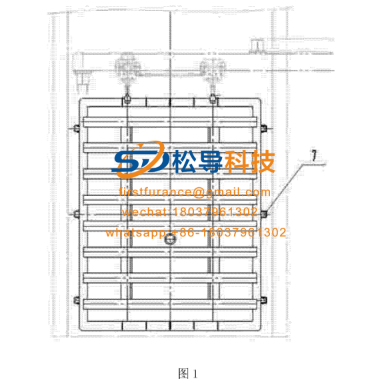

FIG. 1 is a schematic structural view of a front view of a furnace door of a 13T vacuum induction melting furnace.

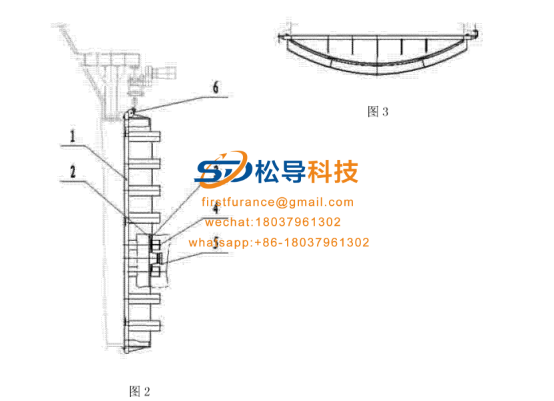

FIG. 2 is a left side view of FIG. 1, and FIG. 3 is a top view of FIG. 1.

In the figure, 1 is a door frame flange, 2 is a circular arc inner plate, 3 is a circular arc outer plate, 4 is a reinforcing rib, 5 is an observation window, 6 is a hanging ring, and 7 is a bracket.

detailed description

The main body is a door frame flange, and two layers of arc plates are welded on it, and cooling water is passed between the two layers of plates to reduce the deformation of the door caused by high temperature radiation in the furnace. Considering that the larger the furnace door, the more pressure it receives when evacuating, so add a few ribs between the horizontal and vertical to ensure its strength. Finally, according to the process requirements, an observation window for observing the conditions in the furnace, a ring for installing the furnace door, and a bracket for pressing the furnace door are added.

The furnace door is welded by the door frame method, the arc door plate and several reinforcing ribs. Compared with the flat plate, the arc plate with the same thickness and the same material can withstand greater pressure, and the furnace door adopts a double-layer water-cooled structure. The radiant heat transmitted to the furnace door can be taken away in time to prevent the furnace door from being deformed due to high temperature.

http://www.songdaokeji.com/plus/list.php?tid=49

http://www.songdaokeji.com/plus/list.php?tid=22