The steel pipe quenching and tempering production line is mainly composed of intermediate frequency power supply , heating sensor, automatic feeding device, press roller rapid discharging device, infrared temperature measuring device and central console. By supporting different sensors, the heating of the workpiece can be realized, the heating temperature and the radial temperature, the axial temperature difference can meet the process requirements, and the insulation can be realized, and the temperature of each steel pipe is automatically recorded . The quenching temperature is 950 ° C , so the heating equipment It adopts intermediate frequency and super audio multi-frequency hybrid heating, and its power and frequency are respectively configured as follows: 250kw/6kHZ ( KGPS intermediate frequency power supply ), 100~200kw/20kHZ , 160kw/50 kHZ ( IGBT super audio induction heating power supply) tempering temperature 425°C It adopts 160kw/6 kHZ intermediate frequency power supply , the production running speed reaches 50~60m/min ( Φ 9 ), and the heating power consumption is 300 KW.t/T . All power supplies have internal and external control functions with current medium voltage double closed loop characteristics to ensure quenching. The tempering temperature does not change with external factors. Since the production line is a continuous uninterrupted working mode, the entire production line is controlled by PLC.With the touch screen, the actual transmission adopts the frequency conversion type to adjust and adjust the whole production line. Compared with the traditional slip motor and DC speed regulation, the control precision is high, the adjustment range is wide, and the operation is more stable.

Equipment name: Steel tube quenching and tempering production line

Workpiece material: Carbon steel alloy steel

Workpiece size: diameter 20 mm or more

Power range: 160- 1000KW

closed-loop temperature control: US Leitai two-color thermometer control temperature

control system: PLC people Machine interface automatic intelligent control

Process description and working process of round pipe, steel tube quenching and tempering production line :

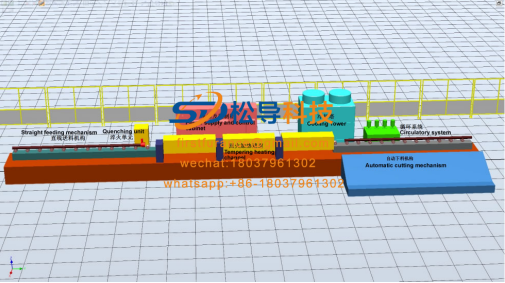

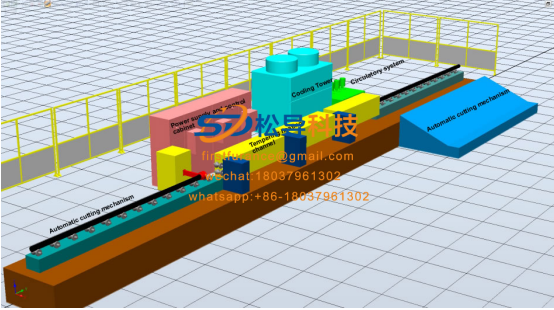

1 , the heat treatment process: steel material placed on the crane gantry by loose bundle → upper feeder feeding → Frequency feed roller steel pipe is fed forward → quenching medium frequency induction heating inductor (low temperature) furnace (high temperature) furnace Heated to 950 °C infrared temperature measurement and feedback to form a closed-loop control to adjust the power of the intermediate frequency induction heating furnace → spray quenching → lift the pipe through the turning machine and put it on the residual water draining device in the pipe → lift the pipe through the turning machine On the tempering roller path → (low temperature) tempering induction heating furnace → (high temperature) tempering medium frequency induction heating sensor (heating) heating to 450 ~ 760 °C infrared temperature measurement and feedback to form a closed loop control to adjust the medium frequency induction heating furnace power → turn Feeder → chain two-way cold bed → turning machine → discharge . ![]()

![]()

2 , steel pipe quenching and tempering production line parameters summary

size | Control System | Supporting power supply |

Φ10- Φ28mm | PLC intelligent control | KGPS350KW + KGPS160KW |

Φ42- Φ48mm | PLC intelligent control | KGPS250KW + KGPS160KW |

Φ30- Φ60mm | PLC intelligent control | KGPS250KW + KGPS160KW |

Φ30- Φ60mm | PLC intelligent control | KGPS250KW + KGPS160KW |

Φ35- Φ60mm | PLC intelligent control | KGPS300KW + KGPS160KW |

Φ30- Φ110mm | PLC intelligent control | KGPS400KW + KGPS160KW |

Φ80- Φ110mm | PLC intelligent control | KGPS600KW + KGPS160KW |

Φ73.2-Φ88.9mm- Φ139.7 mm | PLC intelligent control | KGPS500KW + KGPS100KW |

Φ95- Φ114mm | PLC intelligent control | KGPS250KW + KGPS160KW |

Customized production according to the actual needs of customers | ||

The steel tube quenching and tempering production line adopts intelligent series resonant intermediate frequency power supply control features:

● Parallel resonance design, phase shifting and power adjustment, the equipment is mature and stable; it has more advantages in the high power range above 3000KW .

● DSP control, the speed capture phase lock starts, meets frequent start and stop, and the success rate is 100% .

● Variable frequency variable load adaptation, frequency adaptation range 200-10000Hz, induction furnace replacement automatic matching, no manual adjustment is required.

● T2 copper copper row in the cabinet , sandblasted and passivated; low leakage and anti-oxidation, effectively reducing line loss.

● Full touch screen control, pure digital setting, complete process record and strict hierarchical authority. The main parameters can be restored to the factory settings with one key.

● The device has self-protection function (overcurrent, overvoltage, water pressure, phase loss, undervoltage, overload). If it encounters the situation, the device has self-diagnosis function.

Steel tube quenching and tempering production line configuration and characteristics:

1. Quenching medium frequency power supply range: KGPS160-1300KW

2 , tempering intermediate frequency power supply range: KGPS160-750KW

3 , quenching, tempering sensors (including capacitors, water, gas, etc.)

4 , closed circuit cooling system for intermediate frequency power supply and sensor

5 , copper row connection wire (connection between power cabinet and induction furnace)

6. Input and output system (the workpiece rotates on one side, feeds at a constant speed on one side, and runs smoothly, the speed is adjustable, and the heating is more uniform)

7 , quenching, tempering spray system

8. Quenching and tempering infrared temperature measuring device (with American Leitai infrared thermometer to display the temperature of the workpiece in real time, so that the workpiece can be viewed at any time during the quenching and tempering process)

9 , PLC control system, (can control the operation of the entire mechanical part, man-machine interface, all digital, highly humanized operation)

10 , the central console (including frequency control and temperature control, Huayan IPC, remote start, etc.) its role is to operate the entire quenching and tempering equipment directly on the center console, only one person can operate the entire set of equipment , saving labor and saving costs.