The existing steel cylinder induction heating furnace generally adopts a single direct heating and direct cooling type, that is, the cold bottle directly enters the inductor for heating from the furnace port at one end, heats to the specified temperature for a certain period of time, and then exits the induction heating from the furnace port at the other end. cool down. The disadvantages of this single-layer furnace structure are:

(1) There is much heat loss, large energy consumption and low efficiency;

(2) The steel bottle is heated directly from the cold bottle to the heat treatment temperature, and its temperature rise rate is fast, the temperature in the furnace is not stable, and the temperature is difficult to control. Although the elongation of the material of the steel bottle after heat treatment is improved, its strength is reduced more. In order to overcome the shortcomings of the prior art, a steel bottle induction heating furnace for preheating the cold bottle by using the heat dissipated by the heated high-temperature bottle is provided to improve the thermal efficiency, reduce energy consumption, and ensure the quality of heat treatment .

The steel cylinder induction heating furnace includes a furnace body, a steel cylinder conveying device installed in the furnace body and an intermediate frequency induction heater, etc. The special feature is that the furnace body has a semi-enclosed sealed structure, and the steel cylinder conveying device is an upper and a lower heat exchange section. The lower heat exchange section divides the furnace body into upper and lower layers, and the intermediate frequency induction heater is arranged at the innermost end of the lower layer of the furnace body. Further, the upper and lower heat exchange joints are composed of large sprockets and chains, and are driven by a heat exchange transmission device to radially transfer the steel cylinders. The inner end of the upper heat exchange section of the furnace body is correspondingly provided with a reversing device for axial transmission of the steel cylinder. The reversing device is composed of a sprocket, a chain, a dial on the chain, and a reversing transmission device. There is a cylinder lifting device and a transposition cylinder for pushing the cylinder, which can push the steel cylinder into the intermediate frequency induction heater, and the outlet of the intermediate frequency induction heater is docked with the lower heat exchange joint.

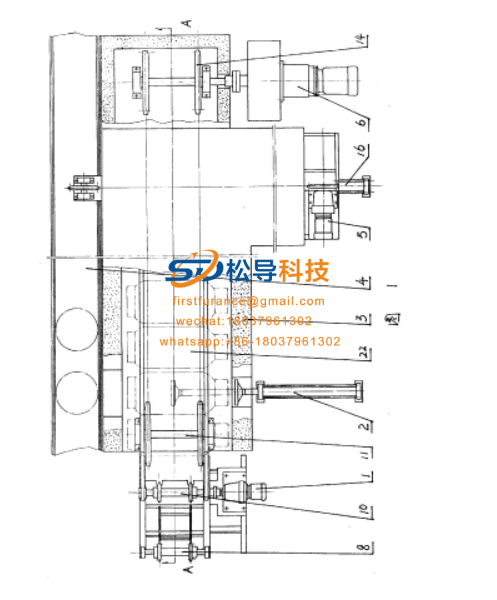

Figure 1 is a schematic view of the top structure of the utility model;

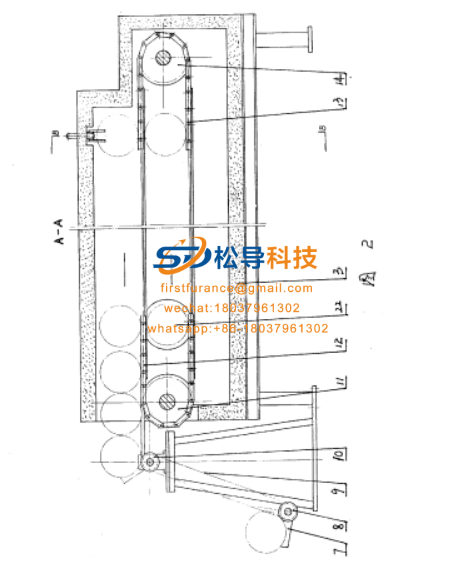

FIG. 2 is a sectional view taken along line AA of FIG. 1 ;

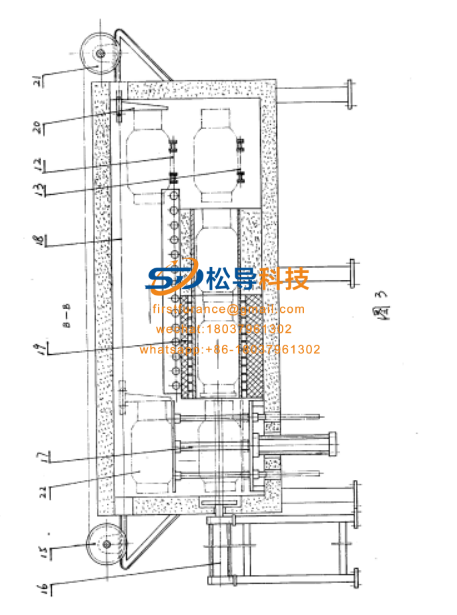

FIG. 3 is a BB sectional view of FIG. 2 .

The structure and advantages of the steel cylinder induction heating furnace will be further described below with reference to the drawings and embodiments .

See Figure 1 , Figure 2 and Figure 3 , mainly including furnace body 3 , upper bottle mechanism, upper heat exchange section 12 , lower heat exchange section 1 3 , reversing device, intermediate frequency induction heater l9 , cylinder lifting device 17 , transposition Push bottle cylinder l 6 , conveyor line 4 etc. The bottle loading mechanism is set at the port of the furnace body 3 , and is composed of the lifting transmission device 1 , the sprockets 8 , 10 , the chain service and the bottle holder 7 , and the steel cylinder 22 is raised to the port 3 of the furnace body radially ; The heat exchange sections 1 2 , 1 3 are composed of large sprockets I 1 , 1 4 , the chain and the heat exchange transmission device 6 , and the steel cylinders 2 2 are conveyed in and out of the furnace body 3 in the radial direction ; the reversing device is composed of sprockets 15 , 2 1 , A chain 18 , a shift fork 20 and a reversing transmission device 5 , and the steel cylinder 22 is axially conveyed in the furnace body 3 .

The working process of the steel cylinder induction heating furnace is this: the bottle feeding mechanism is driven by the lifting transmission device l through the sprockets 8 and 10 to drive the bottle holder 7 on the chain 9 to push the steel bottle 2 2 upward, and send the cold bottle into the furnace body 3 port On the upper heat exchange section l 2 , the upper and lower heat exchange sections 12 and l 3 are driven by the heat exchange transmission device 6 through the large sprockets l I and 14 to move according to the beat. Each movement is a beat, and the upper and lower layers are supplemented with a cylinder 22 , and each cylinder 22 spin 1 "week. when the upper heat exchange section oriented operating cylinder 1. 3 when the end of the f in FIG. 2B-B cross-sectional view position), the commutation of the drive means 5 by a sprocket 1 5 and 2 . 1 driven by a chain 18 fork on 20 the cylinder 22 is pushed to the lifting cylinder means 17 , the lifting cylinder means 17 down in place, the transposition bottle pushing cylinder 16 to the cylinder 22 is pushed into the induction heating The heater 19 is heated, and the previously heated steel cylinder 2 2 is pushed to the lower heat exchange section 13 soil. When the steel 2 2 on the lower heat exchange section 13 runs to the output push cylinder 2 of the outlet , the output push cylinder 2 Push the steel cylinder out of the furnace body 3 to the conveyor line 4 , and thus complete a working process.

This structure makes full use of the heat of the high-temperature hot bottle after induction heating to exchange cold and heat, so that the cold bottle has obtained a higher preheating temperature before entering the induction heating, thereby reducing energy consumption and making the temperature in the furnace tend to smooth. After testing, the present invention is an induction furnace for each treatment cylinder can save a 0.514 kWh annually for each furnace can handle cylinders 54 million, the saving . 3 the I . . 5 million kilowatt hours, saving nearly 36 million yuan, and the heat treatment the cylinder reached the national standard stress relief of the pressure vessel, and ensure the strength and elongation of the material without impairing the cylinder, the cylinder to ensure the quality of heat treatment.