An improvement of multiple induction melting furnaces and water cooling devices used in multiple continuous casting and lashing production lines , in particular, it corresponds to multiple induction melting furnaces and control cabinets used in multiple continuous casting and lashing production lines The multiple water cooling devices are replaced by one cooling device, which simplifies the cooling device and reduces the investment of multiple cooling devices . It is suitable for the water cooling device of continuous casting and continuous production enterprises above medium .

Most of the above-mentioned continuous casting and continuous production enterprises have more than 4 continuous casting and continuous production lines, each continuous casting and continuous production line,

In addition to a continuous casting and rolling outside the machine, but also with an induction melting furnace , a control cabinet, since the induction melting furnace and the need to control cabinet into cold water cooled, but also equipped with a cooling tower, each cooling The tower should also be equipped with circulating water pump and cold

Water tank. For example the company, the existing 19 Article continuous casting and rolling production line, corresponding to 19 units induction melting furnace , and 19 control cabinet, each induction melting furnace and re-configure a control cabinet closed cooling tower and the circulating pump and cold water Tanks, so the entire production workshop needs to be equipped with 19 closed cooling towers and their circulating water pumps and cold water tanks. The shortcomings of the induction melting furnace and water cooling device used by such continuous casting and continuous production enterprises are: First, the large number and large occupied area cause the workshop to be crowded and disordered, which reduces the workshop's utilization area; second, the structure is complex , There are many duplicate equipments, which increases the investment.

Provides a plurality of induction melting furnaces and control cabinet cooling devices that can expand the use area of the workshop, simplify the structure, reduce investment, and are more convenient to use . The multiple induction melting furnaces and the control cabinet heat exchange water centralized circulation cooling device include a row of induction melting furnaces used in multiple continuous casting and binding production lines in the workshop . Each induction melting furnace is installed with a control cabinet side by side. The induction melting furnace is provided with a cold water input pipe that is connected to the inlet end of the spiral cooling pipe in the furnace and a water output pipe that is connected to the outlet end of the spiral cooling pipe in the furnace; similarly, it is provided on each control cabinet The cold water input pipe of the cabinet cooling device and the water output pipe after heat exchange of the cabinet cooling device; characterized in that: the cold water input pipe on each induction melting furnace and the corresponding cold water input of the cabinet cooling device on each control cabinet simultaneously with the cold water pipe manifold input in communication, through a cold-water supply manifold connected to the outlet pressure of the cold water pipe and the input of the pump, the cold-water supply pump inlet through the cold water outside of the cold water tank of cold pipette access workshop; each of said induction melting furnace After the heat exchange, the water output pipe and the corresponding cooling device in each control cabinet are connected to the water output main pipe after heat exchange at the same time. One end of the main pipe is connected to the position above the water surface of the cooling pool outside the workshop through the heat exchange tube. The bottom of the cooling pool and the cold pool are connected through a communication pipe; the cooling pool is provided with a cooling tower on the upper side to cool The tower inlet pipe is connected to the heat exchange water input pump, the suction port of the heat exchange water input pump is connected to the telescopic pipe, the end of the telescopic pipe is connected to the float type suction port, and the cooling water outlet pipe of the cooling tower is connected to the cooling pool. It is also implemented by the following measures: the upper port of the cooling tower is provided with a cold water replenishing nozzle, and the cold water replenishing nozzle is connected to the tap water pipe; Connection, when the temperature of the bottom of the cooling pool has not dropped to normal temperature, the temperature control switch is closed, at this time the solenoid valve switch of the cold water replenishing nozzle is turned on, and cold water is sprayed; otherwise, when the temperature of the bottom of the cooling pool has dropped to normal temperature, the temperature When the control switch is turned on, the solenoid valve switch of the cold water replenishing nozzle is closed, the spray of cold water is stopped, and the water at the bottom of the cooling pool flows into the cold pool at the same time. An axial fan is provided in the upper mouth of the cooling tower, and an air inlet grille is provided at the waist of the cooling tower; the upper part of the inner cavity of the cooling tower has a rotating nozzle, and a row of lower nozzles is provided on the bottom wall of the rotating nozzle. The central lower side of the rotating nozzle is connected to the upper opening of the vertical section of the cooling tower inlet pipe in the cooling tower. The central upper side of the rotating nozzle is connected to the axial end of the axial fan through a damping sleeve. When the axial fan rotates At the same time, at the same time, the resistance of the damping sleeve drives the rotating nozzle to rotate at a low speed, which also prevents the rotating nozzle from escaping from the cooling tower inlet pipe at the vertical section of the cooling tower at the water pressure, through the rotating nozzle and its row The lower nozzle realizes the rotation and splashing of the water with higher temperature entering the cooling tower to expand the heat exchange area; the middle and upper part of the cooling tower is provided with two layers of grids to improve the uniformity of heat exchange and change the different intervals Flow rate and flow status.

An overflow pipe is provided on one side of the cooling pool. The cooling tower, cooling pool, and cold pool are all located on the north side of the workshop to avoid sunlight; the cooling tower and the heat exchange water input pump are installed on the upper side of the cooling pool through the cover plate. There are 18-24 induction melting furnaces and corresponding control cabinets , which are suitable for medium-sized continuous casting and continuous production enterprises. The damping sleeve is made of friction material. For large-scale continuous casting and continuous production enterprises, it can also be used by increasing the cooling capacity of the cooling tower. The plurality of induction melting furnace and the heat exchange cabinet water recirculating coolant system, originally used with a plurality of continuous casting and rolling each production line induction melting furnace and a control cabinet cooling tower as compared to a corresponding, thanks to a cooling tower 18-24 station induction melting furnace 1 and the corresponding control cabinet 2 is cooled, so eliminating the need for 17-23 cooling towers, investment can save 100 million; since the entire cooling towers, pools were built outside the shop, which is not Occupies the workshop area and improves the utilization rate of the workshop; since both air cooling and water cooling are used, the cooling effect of the cooling tower is improved; and a temperature control device is added to ensure that the temperature of the cold pool is normal temperature, thereby ensuring the induction melting furnace And the cooling effect of the control cabinet.

BRIEF DESCRIPTION

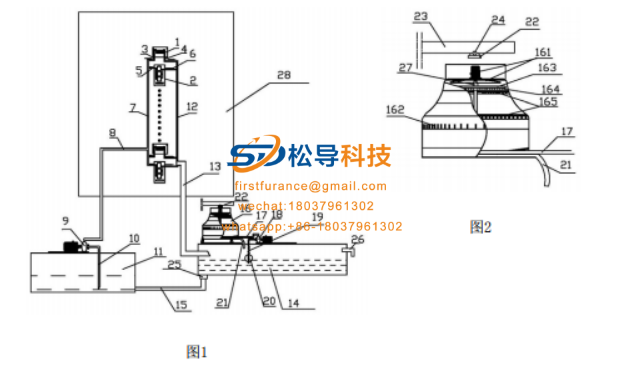

FIG. 1 is a schematic top view of the planar layout structure of the utility model.

detailed description

Refer to Figure 1 and Figure 2 . The heat exchange water of the multiple induction melting furnaces and the control cabinet is circulated and cooled

Cooling means, comprising a plant 28 within a plurality of continuous casting and rolling a plurality of lines used in an induction melting furnace 1 , each induction melting furnace 1 installed side by side a control cabinet 2 , each in an induction melting furnace 1 on average is provided with The cold water input pipe 3 connected to the inlet end of the spiral cooling pipe in the furnace and the water output pipe 4 after heat exchange butted to the outlet end of the spiral cooling pipe in the furnace exchange heat through the spiral cooling pipe in the furnace to realize the cooling of the furnace At the same time, the heat exchange water in the spiral cooling tube is heated; similarly, each control cabinet 2 is provided with a cold water input pipe 5 in the cabinet cooling device and a water output pipe 6 after heat exchange in the cabinet cooling device , through the cold water flow Heat exchange through the cooling device in the cabinet to achieve the cooling of the cabinet; characterized in that: the cold water input pipe 3 on each induction melting furnace 1 and the corresponding cold water input in the cabinet cooling device on each control cabinet 2 tube 5 while the cold-water supply manifold 7 communicated, cold-water supply manifold 7 via a pressure pipe 8 and the cold-water supply pump 9 connected to the outlet, the cold water feed pump 9 the suction port of the suction pipe through the cold 10 access plant 28 outside the cold water tank 11 within the cold water ,through Start cold-water supply pump 9 the cold water tank 11 of cold water into the cold-water supply manifold 7 , and routed to each of the stations induction melting furnace 1 and the control cabinet 2 the cooling device; said each induction melting furnace 1 a heat exchanger on after the water outlet tube 4 of each, and the corresponding control cabinet 2 after the device cabinet cooling water outlet pipe of the heat exchanger 6 while the water heat exchanger and the rear manifold output 12 in communication, the water heat exchanger output manifold 12 after the end of the heat exchanger by The water outflow pipe 13 is connected to the position above the water surface of the cooling pool 14 outside the workshop 28. The bottom of the cooling pool 14 and the cold pool 11 are connected through a communication pipe 15 so that they pass through each induction melting furnace 1 and each control cabinet 2 after the water heat exchanger output water manifold 12 flows into the cooling tank summary 14 , cooling tank 14 after heat exchange, temperature was lowered to room temperature, and then through the communication pipe 15 flows into the cold water tank II within, recycling; the described cooling tank 14 on the side of a cooling tower 16 , cooling tower water inlet pipe 17 connected to exchange water feed pump 18 , for hot-water supply pump 18 of the suction port connected to the bellows 19 , the bellows 19 an end portion connected to a float-type suction mouth 20 , the cooling tower 16 cooling water discharge pipe 21 Into the cooling tank 14 , the water flows out because the heat transfer tube 13 flows out of hot water, lighter weight, so in the cooling tank 14 the upper layer, the input pump hot water by activating the transducer 18 via a float-type suction port 20 of the cooling water tank 14 the upper temperature higher water into the cooling tower 16 inside, in the cooling tower 16 water in the cooling down and then flows into the cooling water tank 14 the upper layer, through continuous circulation cooling, allows the cooling pond 14 of water in the down to room temperature, down to room temperature cooling water tank 14 lower; As a result of the float suction port 20 , so regardless of the cooling water tank 14 the water level in how changes, always extraction cooling tank 14 the upper layer of water. Cooling tower 16 catchy supplemented with cold water spray head 22 , cold water supplemented nozzle 22 connected to the water pipe 23 , through water pipe 23 the pressure in the cold water supplemental nozzle 22 automatic sprinkler, since the circulating cooling water, a certain amount of water consumption, thus, can be added through the cold head 22 to achieve a spray of water added, while achieving water-cooled; the complementary cold head 22 solenoid valve switch 24 via a line with a cooling water tank 14 the bottom of the communicating pipe 15 temperature-dependent switch inlet 25 Reverse connection, when the temperature of the bottom of the cooling pool 14 has not dropped to normal temperature, the temperature control switch 25 is closed, at this time the solenoid valve switch 24 of the cold water replenishing nozzle 22 is turned on, and cold water is injected; otherwise, when the temperature of the bottom of the cooling pool 14 has When the temperature drops to normal temperature, the temperature control switch 25 is turned on, and the solenoid valve switch 24 of the cold water replenishing spray head 22 is closed to stop spraying cold water, and at the same time, the water at the bottom of the cooling pool 14 flows into the cold pool 11 . Cooling tower 16 catchy features are axial fan 161 , cooling tower 16 is provided with waist gate inlet 162 , through the axial flow fan 161 induced draft air inlet and outwardly gate 162 inlet air to achieve, by this and simultaneously cooled air to improve the cooling tower 16 cooling effect; cooling tower of claim 16 upper interior portion of the rotating nozzle 163 , the rotary nozzle 163 is provided with a row of lower nozzle bottom wall 164 , rotation of the nozzle 163 The lower part of the middle is connected to the upper part of the vertical section of the cooling tower inlet pipe 17 in the cooling tower 16 , and the upper side of the rotating nozzle 163 is connected to the axial end of the axial fan 161 through the damping sleeve 27. When the axial flow When the fan 161 rotates, at the same time, the resistance of the damping sleeve 27 drives the rotating nozzle 163 to rotate at a low speed, which also prevents the rotating nozzle 163 from escaping from the cooling tower inlet pipe 17 at the upper opening of the vertical section of the cooling tower 16 under the pressure of water . By rotating the nozzle 163 and a row of lower nozzles 164 , the water that enters the cooling tower 16 with a higher temperature can be rotated and sprinkled to expand the heat exchange area; the middle and upper part of the cooling tower 16 is provided with two layers of grids 165 , To improve the uniformity of heat exchange and change the different areas The velocity and flow condition. An overflow pipe 26 is provided on one side of the cooling pool 14 . The cooling tower 16 , cooling pool 14 and cold pool 11 are all located on the north side of the workshop 27 to avoid sunlight; the cooling tower 16 and the heat exchange water input pump 18 are installed in the cooling pool through the cover plateThe upper side of 14 . The damping sleeve 27 is made of friction material. Through the implementation proof: after use, 18 cooling towers are used less , each cooling tower is 70,000 yuan, which can reduce the investment of 1.26 million yuan; the workshop area is less than 530 square meters, and the workshop utilization rate is increased by 13.3% .