The lining of the induction melting furnace in the silver smelting process is generally produced by knotting the solid charge . Because the furnace lining is greatly affected by temperature changes, after repeated heating and cooling, the chemical stability is reduced, and it is easy to be washed away and peeled off. The high temperature stamping resistance is significantly reduced, and the furnace wear phenomenon is easy to occur. To meet the needs of continuous production, while increasing maintenance costs.

A specific method for improving the induction melting furnace: The lining structure of the induction melting furnace includes an asbestos cloth layer, a solid charge layer, and a graphite crucible from the outside to the inside . It is characterized in that the thickness of the solid charge layer is 150-200mm, and the solid charge is corundum knotted. The graphite crucible is 50-60mm thick. The graphite crucible and solid charge are used . Because graphite has good high temperature resistance, it can withstand the erosion of high temperature silver melt, reducing impurities into the anode plate. At the same time, graphite does not bring impurities to the silver anode plate, which improves the anode plate. quality; Since the graphite crucible surface smooth, non-sticking silver, to ensure that the induction melting furnace within the silver melt all to enter the casting system, improve the operating efficiency of a single furnace; graphite crucible plus play real charge to ensure that the production process induction melting furnace temperature stabilization, the silver melt condensation does not occur, thereby saving energy consumption. The induction melting furnace is installed with a graphite crucible and a solid charge , which is convenient for maintenance operations, reduces the frequency of maintenance, reduces the cost of maintenance, improves the operating efficiency, eliminates the phenomenon of furnace wear and damages the equipment, and ensures the safe and stable operation of production. The life of the lining of the solid kiln charge + graphite dry pot knotted molding is 60-100 times, and the induction melting furnace system meets the requirements of safe and civilized production and environmental protection. The use process is convenient and concise, the operability is strong, the production cost is reduced, and it has good use value.

BRIEF DESCRIPTION OF THE DRAWINGS

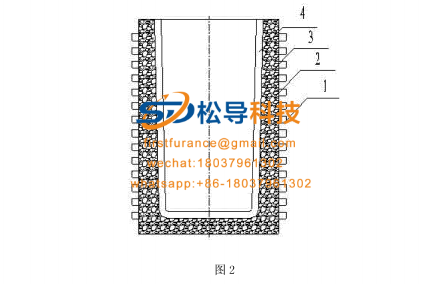

FIG. 1 is a schematic structural diagram of the present invention;

FIG. 2 is a top view of FIG.