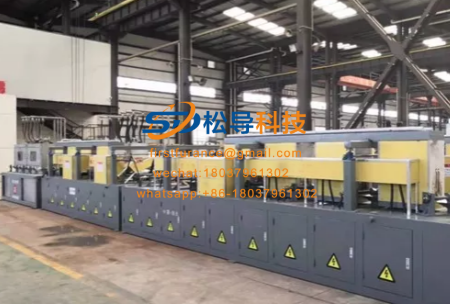

The intermediate frequency quenching and tempering production line consists of two parts: quenching and tempering; the quenching heating part is composed of three sets of medium frequency power supplies with different powers and two sets of heating induction coils ; 600kW/2 to 4 kHz power supply with four sets of 600mm quenching and heating sensors; 75kW/ . 4 ~ 8kHz power supply with a set of two sets of 600mm quenching heat sensor; 75kW /. 8 ~ 16kHz power supply with a set of two sets of 600mm quenching heat sensor.

IF quenched line tempering heating power in part by three different frequency power supply with a plurality of sets of induction heating coils; 360KW /. 1 ~ 2kHz power with a set of 6 units 600mm tempering heating sensor; 45kW / 2 ~ 4kHz power strips a group of 3 units 600mm tempering sensors, 45kW /. 4 ~ 8kHz power supply with a set of 3 units 600mm tempering sensor; wherein further including quenching and tempering shower spray section, and the air cooling section and the corresponding transition section .

The basic conditions and technical requirements of this quenching and tempering production line are as follows:

1 , process, technical parameters

1.1 , round steel diameter range (mm) : φ 24 ~ Φ 80

1.2 , round steel length range ( m ) : 2m ~ 7m

1.3 , round steel material: 35# , 45# , 40Cr, 42CrMo, 40CrNiMo, etc.

1.4 , product performance level: 5.6 , 8.8 , 10.9 , implementation standards: GB/T3098.1

1.5 , quenching temperature range: 820 °C ~ 920 °C

1.6 , tempering temperature range: 420 °C ~ 750 °C

1.7 After the quenching and tempering , the hardness of the core of the round steel end is the maximum length ( mm ): 50mm

(Note: the core hardness at 50mm at the end is consistent with the hardness at any point within 50mm length)

1.8 , straightness tolerance of round steel after quenching and tempering φ t : t=0.0025 ∫ [∫ is the length of round steel ( mm ), straightness of round steel before quenching and tempering φ t=0.002 ∫]

1.9 , the maximum production volume: an average of 2t / h per hour , with φ 56 diameter specifications acceptance.

2.0 , equipment production acceptance requirements:

A, the diameter of the acceptance round steel is φ 30 ( 40Cr ), φ 56 ( 42CrMo ), φ 76 or φ 80 ( 42CrMo )

B, the performance levels are: 8.8 and 10.9 , the acceptance performance requirements and test requirements are in accordance with GB/T3098.1 .

2 , device performance description

2.1. Feeding by means of inclined roller, the workpiece is conveyed at a constant speed in the state of rotation. The conveying line is controlled by frequency conversion, and the feeding, sensing and discharging are controlled separately. The roller of the inductor part is made of stainless steel and cooled by water.

2.2. Adopt automatic feeding and automatic cutting; in order to facilitate the bundling and lifting after cutting, the feeding platform is U -shaped; the upper and lower loading tables are welded with high-quality steel and can withstand certain impact loads.

2.3. According to the safety standardization requirements of the machinery industry, all mechanical rotating exposed parts have reliable protective covers; the production line should comply with national environmental protection standards.

2.4. The intermediate frequency power supply adopts the components of well-known domestic brands, which is reliable in use and low in failure rate. The power supply has water temperature, water pressure, short circuit and voltage loss protection.

2.5. The winter temperature of the production site is -5 °C. In order to ensure that the equipment is not damaged by freezing, the equipment has reliable anti-freezing measures and measures for discharge water protection;

2.6. In-line infrared temperature monitoring is set in the quenching and tempering process respectively, and the domestic thermometer is used.

2.7. All production processes are automatically controlled by computer, and each division can also be converted to manual control. The computer control software requires convenient input and adjustment of process parameters, and has query and storage functions. The control software is a successfully running software, 10 -inch touch screen.

2.8. The appearance is colored gray, the primer is applied twice, and the topcoat is painted twice.