Equipment name: 150KW digital high frequency unit

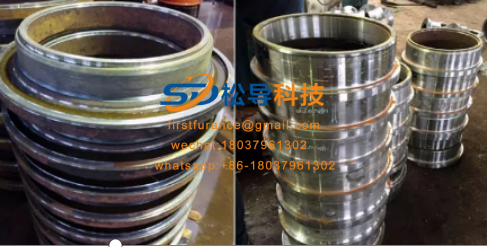

Applicable to: ring parts (large diameter ring, sleeve, roller, etc.); (end face, outer face, groove, etc. quenching )

Machinable parts diameter: 150mm--1750mm ;

Machinable parts: outer circular surface, end surface, groove, plane, etc.

Heat treatment process : surface hardening, local hardening

Induction hardening (medium, high, super audio) is mostly used for surface quenching of industrial metal parts. It is a metal heat treatment method that generates a certain induced current on the surface of the workpiece, rapidly heats the surface of the part, and then rapidly quenches. Induction heating equipment, that is, equipment that inductively heats a workpiece for surface hardening. Principle of induction heating: The workpiece is placed in the inductor. The inductor is usually a hollow copper tube with input intermediate frequency or high frequency alternating current (1000-300000 Hz or higher ) . The alternating magnetic field generates an induced current of the same frequency in the workpiece. The induced current is uneven in the distribution of the workpiece, strong on the surface, and weak inside, to the core close to 0 , using this skin effect The surface of the workpiece can be heated rapidly, and the surface temperature rises to 800-1000 ° C in a few seconds , while the core temperature rises little. Advantages : high hardness: the heating rate is extremely fast, so the transformation temperature is increased, thereby achieving the purpose of refining the crystal grains, and the microstructure is strengthened due to the fine grain. Small deformation: Because of local hardening, the overall deformation of the workpiece becomes small.Surface stress resistance: fatigue resistance.