A, use:

Medium frequency melting furnace - molten iron, molten steel, molten aluminum, molten copper dedicated 0.25T-60T intermediate frequency melting furnace.

B, the basic composition of the intermediate frequency melting furnace

1000kw intermediate frequency power supply (parallel inverter ), resonant capacitor bank, 400mm 2 water-cooled cable, 1T furnace body (steel shell or aluminum shell) C, 1000kw medium frequency power supply advantages:

Constant power output, faster melting speed and more obvious power saving effect.

Zero-voltage sweep software is started, which is more suitable for frequent start-up requirements.

The protection measures are comprehensive, such as overcurrent, overpressure, current limiting, pressure limiting, water shortage, and lack of equal protection. Under the premise of ensuring the melting speed, the equipment is reliable. Simple to operate, suitable for a variety of casting processes.

D, furnace introduction

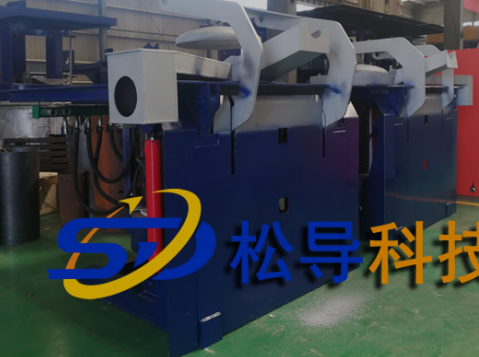

The shell structure is divided into two structures: aluminum shell furnace and steel shell furnace :

The small-capacity furnace shell is generally made of aluminum alloy, which has reasonable structure, small volume, convenient installation, simple maintenance and low maintenance cost.

The large-capacity furnace body shell adopts a steel frame structure, and the furnace body structure is composed of a furnace fixing frame and a furnace body, and the furnace fixing frame and the furnace body adopt an integral skeleton structure. The tilting of the furnace body is controlled by the hydraulic system, which is realized by lifting two hydraulic cylinders on both sides of the furnace body. The resetting of the furnace body is realized by the pressure generated by the self-weight of the furnace body.

F, yoke

The furnace body has a built-in yoke, and the yoke shield can reduce the magnetic flux leakage, prevent the furnace body from heating and improve the efficiency. At the same time, the yoke acts as a support for fixing the induction coil, so that the furnace body achieves high strength and low noise. The yoke is a crescent-shaped yoke made of cold-rolled silicon steel sheet and stainless steel splint. The joint surface of the iron core and the coil is a circular arc surface, and the pressing portion is a surface instead of a line in the past. Good, less magnetic leakage. After the silicon steel sheets are stacked, they are tightened with a special splint instead of a special threaded screw. This structure can make full use of the magnetic conductive area of the silicon steel sheet and reduce the possibility of local heat generation.

G, coil (induction coil)

The coil is the heart of the intermediate frequency melting furnace . The induction coil generates a strong magnetic field under the action of current, which causes the metal in the furnace to generate eddy currents and generate heat. Coils are the key to converting electrical energy into heat, so the design of the coil is very important. The coil of the furnace is combined with the actual use of the intermediate frequency melting furnace . According to the principle of electromagnetic field, the better solution determined by the calculation of computer professional software, the error between the design power of the induction coil and the actual running power is not more than 5%, and the insulation of the coil In particular, the inter-turn insulation is protected by an advanced insulation method, and the special clamping technology can effectively reduce the axial vibration of the coil. The inner wall of the induction coil is coated with imported high-temperature insulation material, and is equipped with a leak alarm system, which can effectively prevent the furnace from being worn. Optional furnace lining and ejection mechanism can quickly remove the damaged lining and facilitate the rapid furnace construction.